Contract Manufacturing Services

Micronize and Refine

Contact usGfM is focused on building long-term relationships and always looking for new ways to improve through technology and smart investments.Whether you are developing new formulations, working with specialized materials, or planning a scale-up for production, we can provide tailored services for your specific project needs.

We efficiently reduce the particle size of raw materials, intermediates, and finished products. For coarser particle sizes, we use advanced mechanical milling technologies like hammer mills, pin disc mills, and conical sieve mills. Each process is adapted to suit your product's specific needs while protecting sensitive compounds.

Achieving small and consistent particle sizes is crucial for enhancing solubility, bioavailability, and formulation performance. At GfM, we specialize in reducing solid particles up to micrometer-scale dimensions even smaller than 1 µm. To achieve these results, we use various micronization technologies, including spiral jet mills, fluidized bed jet mills, and ultra-rotor air turbulence mills.

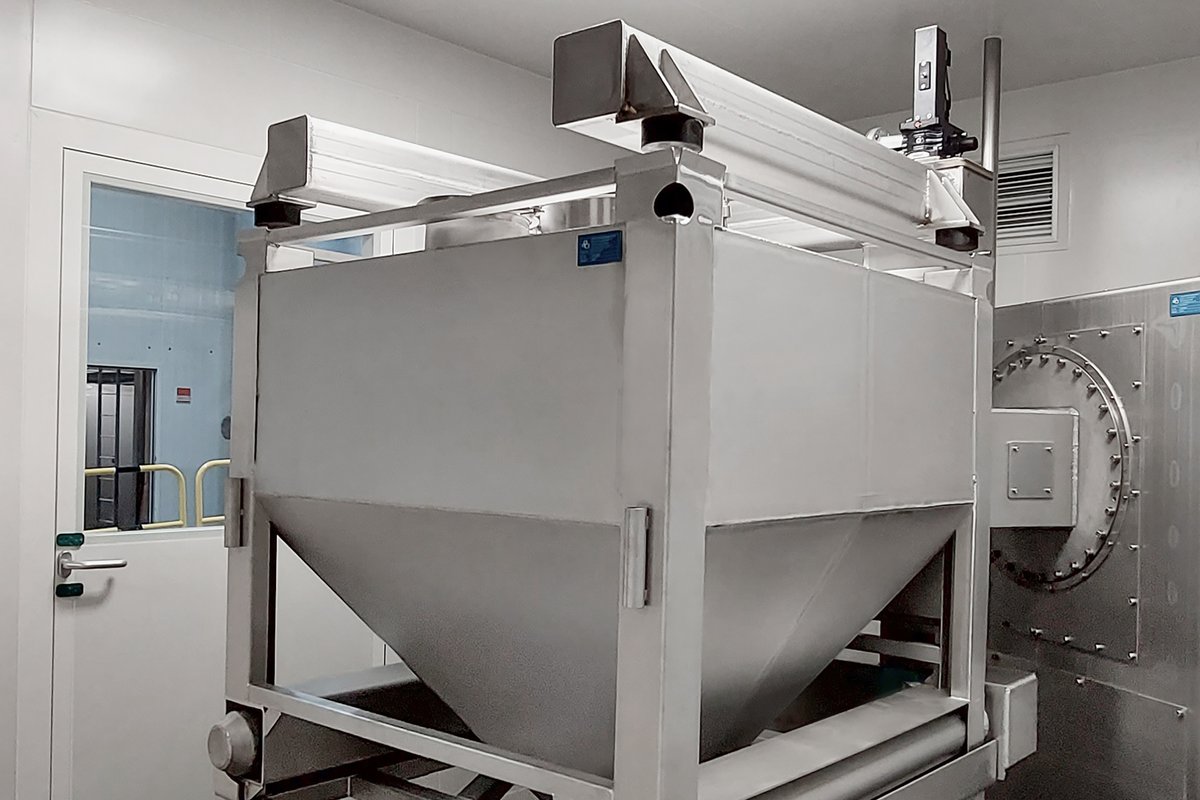

We offer sterile milling and micronization services conducted under aseptic conditions in Class A cleanrooms following the highest pharmaceutical manufacturing standards. Our sterile processes at GfM assure zero tolerance for microbial contamination as we thoroughly perform contamination controls that require validated aseptic processing, environmental monitoring, and sterility assurance levels (SAL).

For the micronization of high potent APIs, a jet mill in a contained environment is available at GfM. The containment system ensures maximum operator safety und product integrity without compromising performance. It allows particle size reduction for HPAPIs up to OEB Level 4 and 5.

Certain materials, such as specialty chemicals, waxes, and polymers, require specialized milling techniques due to their sensitivity to heat, elasticity, or low melting points. At GfM, we operate a cryogenic milling process to address these challenges with precision and control. By using liquid nitrogen to cool the materials during milling, we effectively prevent thermal degradation, preserve product integrity, and achieve consistent, ultra-fine particle sizes, even for difficult-to-process substances.

We offers advanced fractionated sieving solutions to classify powders into well-defined size ranges for precise particle size distribution (PSD). We separate powders into specific fractions based on your requirements. This service can be performed independently or as part of an integrated manufacturing workflow. No matter the application, we ensure your material meets exact specifications for particle size, flowability, and product consistency.

As part of our manufacturing services, GfM provides homogenization and blending processes that ensure the uniform distribution of active ingredients and excipients in your formulation. We precisely adapt each blending process to the physical characteristics of your product to establish homogeneity across every batch.

At GfM, we combine technical experience and regulatory knowledge to create custom solutions for your project to help bring your product to market safely and efficiently. We support you in process development and validation for micronization and particle processing. From early feasibility trials to full-scale commercial validation, we ensure your manufacturing process is reproducible and fully compliant with cGMP standards.

Let's make it Finer together.

Let us know what challenges you are trying to solve so we can help.